مرور نظاممند فناوریهای توانمندساز صنعت 4/0 در نت پیشبینانه صنایع دفاعی

چکیده

هدف: این پژوهش با هدف شناسایی و تحلیل فناوریهای صنعت 4/0 در حوزه نگهداری پیشبینانه صنایع دفاعی و بررسی چالشهای پیادهسازی آن انجام شده است.

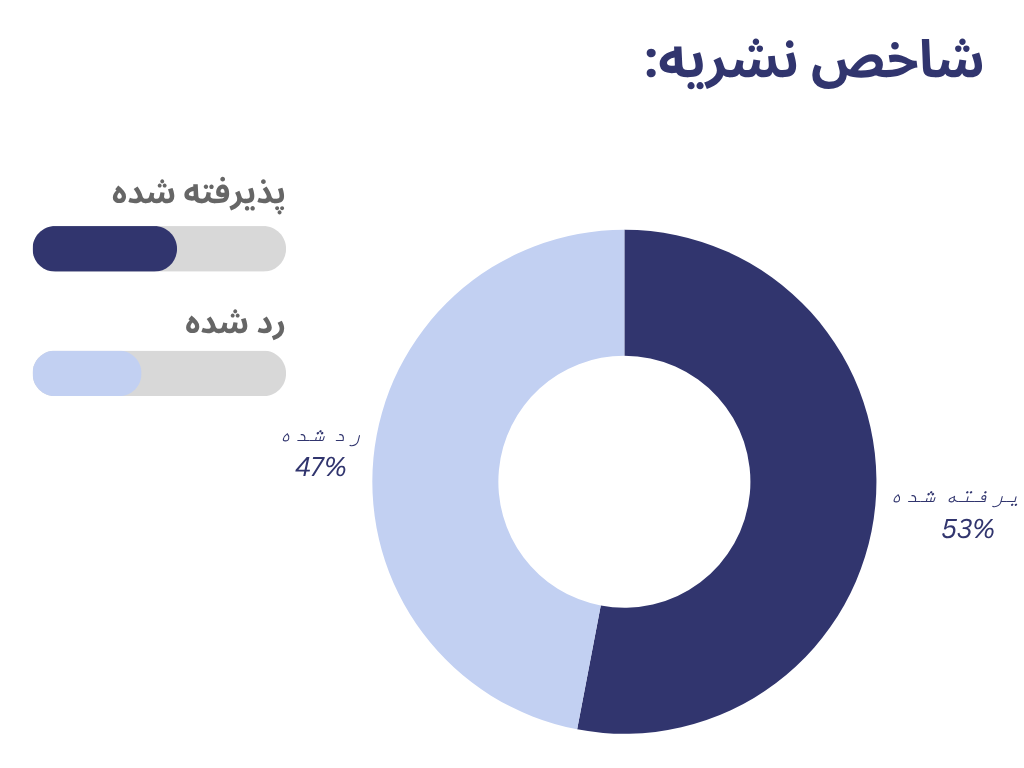

روششناسی پژوهش: مطالعه حاضر یک مرور نظاممند بر اساس PRISMA 2020 است که از بین ۳۰۰ منبع اولیه، ۱۲ مطالعه نهایی را انتخاب و تحلیل کرده است.

یافتهها: اینترنت اشیا و یادگیری ماشین پرکاربردترین فناوریها بودند. اصلیترین چالشها شامل کیفیت داده، امنیت سایبری، محدودیت زیرساخت و کمبود نیروی متخصص است.

اصالت/ارزش افزوده علمی: این پژوهش با تمرکز بر الزامات امنیتی صنعت دفاع، چارچوبی کاربردی برای پیادهسازی نگهداری هوشمند ارایه میدهد و میتواند مبنای تصمیمگیری راهبردی در این حوزه باشد.

کلمات کلیدی:

نگهداری پیشبینانه ، صنعت ۴٫۰، اینترنت اشیا، یادگیری ماشین، صنایع دفاعی، مرور نظاممندمراجع

- [1] Dalzochio, J., Kunst, R., Barbosa, J. L. V., Neto, P. C. D. S., Pignaton, E., Ten Caten, C. S., & da Penha, A. D. L. T. (2023). Predictive maintenance in the military domain: A systematic review of the literature. ACM computing surveys, 55(13s), 1-30. https://doi.org/10.1145/3586100

- [2] Nguyen, K. A., Do, P., & Grall, A. (2015). Multi-level predictive maintenance for multi-component systems. Reliability engineering & system safety, 144, 83–94. https://doi.org/10.1016/j.ress.2015.07.017

- [3] Wang, J., Zhang, L., Duan, L., & Gao, R. X. (2017). A new paradigm of cloud-based predictive maintenance for intelligent manufacturing. Journal of intelligent manufacturing, 28(5), 1125–1137. https://doi.org/10.1007/s10845-015-1066-0

- [4] ur Rehman, M. H., Ahmed, E., Yaqoob, I., Hashem, I. A. T., Imran, M., & Ahmad, S. (2018). Big data analytics in industrial IoT using a concentric computing model. IEEE communications magazine, 56(2), 37–43. https://doi.org/10.1109/MCOM.2018.1700632

- [5] Silver, D., Huang, A., Maddison, C. J., Guez, A., Sifre, L., Van Den Driessche, G., ... & Hassabis, D. (2016). Mastering the game of Go with deep neural networks and tree search. Nature, 529(7587), 484–489. https://www.nature.com/articles/nature16961

- [6] Sun, P., Feng, W., Han, R., Yan, S., & Wen, Y. (2019). Optimizing network performance for distributed dnn training on gpu clusters: Imagenet/alexnet training in 1.5 minutes. https://arxiv.org/abs/1902.06855

- [7] Wang, H., & Pham, H. (2006). Reliability and Optimal Maintenance of Series Systems with Imperfect Repair and Dependence. In Reliability and optimal maintenance (pp. 91-110). Springer. https://doi.org/10.1007/1-84628-325-6_5

- [8] Ponemon Institute. (2011). Cost of data center outages. https://www.ponemon.org/local/upload/file/2011 Cost_of_Data_Center_Outages.pdf

- [9] Gong, X., & Qiao, W. (2014). Current-based mechanical fault detection for direct-drive wind turbines via synchronous sampling and impulse detection. IEEE transactions on industrial electronics, 62(3), 1693–1702. https://doi.org/10.1109/TIE.2014.2363440

- [10] Bevilacqua, M., & Braglia, M. (2000). The analytic hierarchy process applied to maintenance strategy selection. Reliability engineering & system safety, 70(1), 71–83. https://doi.org/10.1016/S0951-8320(00)00047-8

- [11] Carvalho, T. P., Soares, F. A., Vita, R., Francisco, R. da P., Basto, J. P., & Alcalá, S. G. S. (2019). A systematic literature review of machine learning methods applied to predictive maintenance. Computers & industrial engineering, 137, 106024. https://doi.org/10.1016/j.cie.2019.106024

- [12] Samadzad Ettahdi, S., & Yaghmaei Moghadam, M. H. (2021). Engineering and analysis of big and streaming data in the industrial internet of things (IIoT) and its application in the next generation of predictive maintenance (PdM) systems. The 5th international conference on internet of things and applications, isfahan, Iran. Civilica. (In Persian). https://civilica.com/doc/1238617/

- [13] Lei, Y., Yang, B., Jiang, X., Jia, F., Li, N., & Nandi, A. K. (2020). Applications of machine learning to machine fault diagnosis: A review and roadmap. Mechanical systems and signal processing, 138, 106587. https://doi.org/10.1016/j.ymssp.2019.106587

- [14] Li, X., Jiang, H., Hu, Y., & Xiong, X. (2018, August). Intelligent fault diagnosis of rotating machinery based on deep recurrent neural network. In 2018 International conference on Sensing, Diagnostics, prognostics, and control (SDPC) (pp. 67-72). IEEE. https://doi.org/10.1109/SDPC.2018.8664931

- [15] Rahmani, M., & Alizade, H. (2021). Applications of artificial intelligence technology in intelligent command and control systems. Iranian Journal of Wargaming, 4(8), 77-101. (In Persian). http://www.ijwg.ir/article_171125.html?lang=en

- [16] Zhukabayeva, T., Zholshiyeva, L., Karabayev, N., Khan, S., & Alnazzawi, N. (2025). Cybersecurity solutions for industrial internet of things–edge computing integration: Challenges, threats, and future directions. Sensors, 25(1), 213. https://doi.org/10.3390/s25010213

- [17] Bayraktar, O., & Ataç, C. (2018). The effects of Industry 4.0 on human resources management. In Institutions and socio-economic performance: macro and micro perspectives (pp. 337-359). Peter Lang. https://avesis.ticaret.edu.tr/yayin/35b8d867-16ee-4b34-97f4-a48f115b8ecd/the-effects-of-industry-4-0-on-human-resources-management

- [18] Schlötzer, F. (2015). Industry 4.0: The world of smart factories [Thesis]. https://research-api.cbs.dk/ws/portalfiles/portal/58442891/Fabian_Schl_tzer.pdf.

- [19] Ajli, M., & Saberifard, N. (2021). The emergence of the fourth industrial revolution and the development of digital banking. The first national conference on digital transformation and intelligent systems, Larestan, Iran. Civilica. (In Persian). https://civilica.com/doc/1383965/

- [20] Gajek, A., Fabiano, B., Laurent, A., & Jensen, N. (2022). Process safety education of future employee 4.0 in Industry 4.0. Journal of loss prevention in the process industries, 75, 104691. https://doi.org/10.1016/j.jlp.2021.104691

- [21] Munera, E., Poza-Lujan, J. L., Posadas-Yagüe, J. L., Simo, J., Blanes, J. F., & Albertos, P. (2015). Control kernel in smart factory environments: Smart resources integration. 2015 IEEE international conference on cyber technology in automation, control, and intelligent systems (CYBER) (pp. 2002–2005). IEEE. https://doi.org/10.1109/CYBER.2015.7288255

- [22] Fernandez-Carames, T. M., & Fraga-Lamas, P. (2019). A review on the application of blockchain to the next generation of cybersecure Industry 4.0 smart factories. IEEE access, 7, 45201–45218. https://doi.org/10.1109/ACCESS.2019.2908780

- [23] Scaife, A. D. (2024). Improve predictive maintenance through the application of artificial intelligence: A systematic review. Results in engineering, 21, 101645. https://doi.org/10.1016/j.rineng.2023.101645

- [24] Arafat, M. Y., Hossain, M. J., & Alam, M. M. (2024). Machine learning scopes on microgrid predictive maintenance: Potential frameworks, challenges, and prospects. Renewable and sustainable energy reviews, 190, 114088. https://doi.org/10.1016/j.rser.2023.114088

- [25] Feldmann, S. (2018). Predictive maintenance–from data collection to value creation. https://www.rolandberger.com/en/Insights/Publications/Predictive-maintenance-from-data-collection-to-value-creation.html

- [26] Mallioris, P., Aivazidou, E., & Bechtsis, D. (2024). Predictive maintenance in Industry 4.0: A systematic multi-sector mapping. CIRP journal of manufacturing science and technology, 50, 80–103. https://doi.org/10.1016/j.cirpj.2024.02.003

- [27] Pióro, Ł., Sychowiec, J., Kanciak, K., & Zieliński, Z. (2024). Application of attribute-based encryption in military internet of things environment. Sensors, 24(18), 5863. https://doi.org/10.3390/s24185863

- [28] Green, M. (2024). The use of big data in predictive maintenance for aerospace systems. American journal of aerospace and aeronautical engineering, 5(6), 11–15. https://australiansciencejournals.com/ajaae/article/view/536

- [29] Madusanka, N. S., Fan, Y., Yang, S., & Xiang, X. (2023). Digital twin in the maritime domain: A review and emerging trends. Journal of marine science and engineering, 11(5), 1021. https://doi.org/10.3390/jmse11051021

- [30] Sengupta, P., Mehta, A., & Rana, P. S. (2023). Predictive maintenance of armoured vehicles using machine learning approaches. https://arxiv.org/abs/2307.14453

- [31] Pasdar, A., Koroniotis, N., Keshk, M., Moustafa, N., & Tari, Z. (2024). Cybersecurity solutions and techniques for internet of things integration in combat systems. IEEE transactions on sustainable computing, 10(2), 345–365. https://doi.org/10.1109/TSUSC.2024.3443256

- [32] Salhaoui, M. (2021). Smart IoT monitoring and real-time control based on autonomous robots, visual recognition and cloud/edge computing services [Thesis]. https://doi.org/10.31428/10317/10416

- [33] Scott, M. J., Verhagen, W. J. C., Bieber, M. T., & Marzocca, P. (2022). A systematic literature review of predictive maintenance for defence fixed-wing aircraft sustainment and operations. Sensors, 22(18), 7070. https://doi.org/10.3390/s22187070

- [34] Moghtadaei, A. (2024). Aircraft engine maintenance and digital Twin technology in aircraft engines. J data analytic eng decision making, 1(1), 1–5. https://www.researchgate.net/profile/Anahita-Moghtadaei/publication/381587777

- [35] Dalzochio, J., Kunst, R., Barbosa, J., De Freitas, E. P., & Binotto, A. (2023). MILPdM: A predictive maintenance architecture for the military domain. 2023 international conference on machine learning and applications (ICMLA) (pp. 2026–2032). IEEE. https://doi.org/10.1109/ICMLA58977.2023.00306

- [36] Kciuk, S., Krzystała, E., Mkeżyk, A., & Szmidt, P. (2021). The application of microelectromechanical systems (MEMS) accelerometers to the assessment of blast threat to armored vehicle crew. Sensors, 22(1), 316. https://doi.org/10.3390/s22010316

- [37] Frazier, W. (2022). Predictive maintenance using machine learning and existing data sources [Thesis].

- [38] Gholam Nejad, P., Gholami, M., & Pourmakary, A. (2019). Military applications of the internet of things, with emphasis on IR Iran Air Force missions. Military science and tactics, 15(49), 141-163. (In Persian). https://doi.org/10.22034/qjmst.2019.38084

- [39] Zeb, S., & Lodhi, S. K. (2025). AI for predictive maintenance: Reducing downtime and enhancing efficiency. Enrichment: journal of multidisciplinary research and development, 3(1), 135–150. https://doi.org/10.55324/enrichment.v3i1.338

- [40] Kolo, F. H. O. (2025). From framework to practice: Barriers and enablers to RMF adoption in mid-sized enterprises. Asian journal of research in computer science, 18(5), 459–479. https://doi.org/10.9734/ajrcos/2025/v18i5667

- [41] Beheshti Atashgah, M., Barari, M., Bayat, M., & Aref, M. R. (2018). Concepts and security challenges of the military internet of things, focusing on the United States MIoT mechanism. Command and control quarterly, 2(3), 64-78. (In Persian). https://ic4i-journal.ir/browse.php?a_id=93&sid=1&slc_lang=fa

- [42] Alinezhad, A., Azar, D., & Sajadi, V. (2023). Application of internet of things technology in cyber and electronic warfare. Military science and tactics, 19(65), 29–68. (In Persian). https://www.qjmst.ir/article_710159_en.html?lang=fa#:~:text=10.22034/qjmst.2024.556192.1738

- [43] Mozaffari, M. M., & Saberifard, N. (2016). A dictionary of abbreviations in management. Qazvin Academic Jihad Publications. (In Persian). https://b2n.ir/zn5794